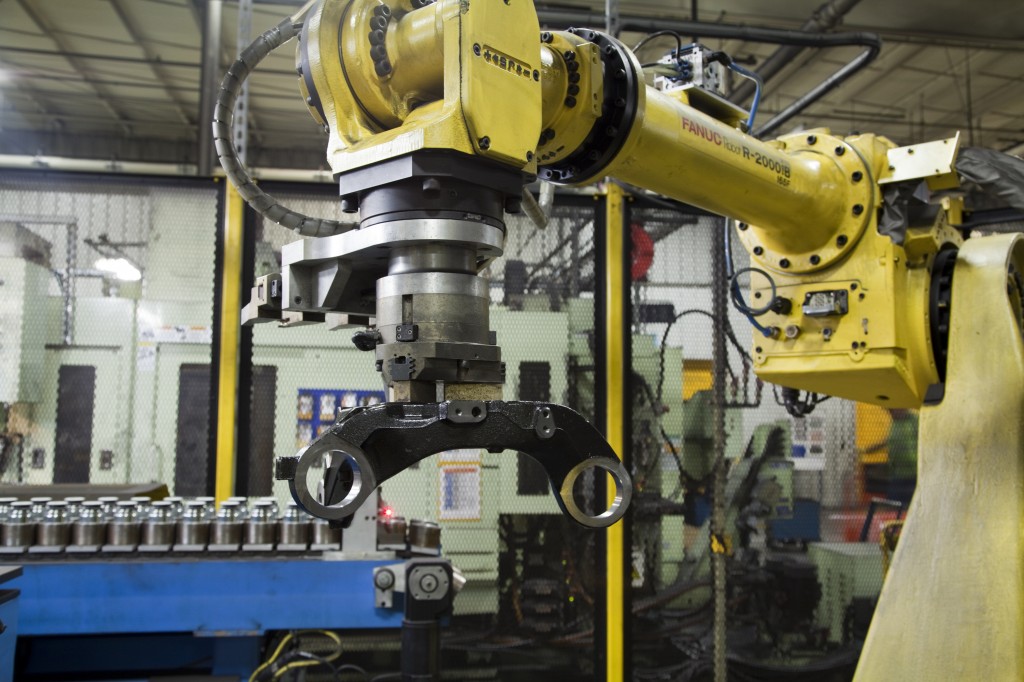

ATTC's Plant Environment:

The ATTC Recycling Program strives to develop a culture where all Team Members understand and practice daily recycling activities with the goal of maintaining a healthy and vibrant environment. A special team has been assembled as part of our company’s Grass Roots program. This team focuses on reducing landfill by recycling cardboard, paper, plastic, scrap metal, and metal shavings from our machining process.